Anjing Road, Xiaolan, Zhongshan, Guangdong, China

info@mes-drive.com

08.00 AM-09.00 PM

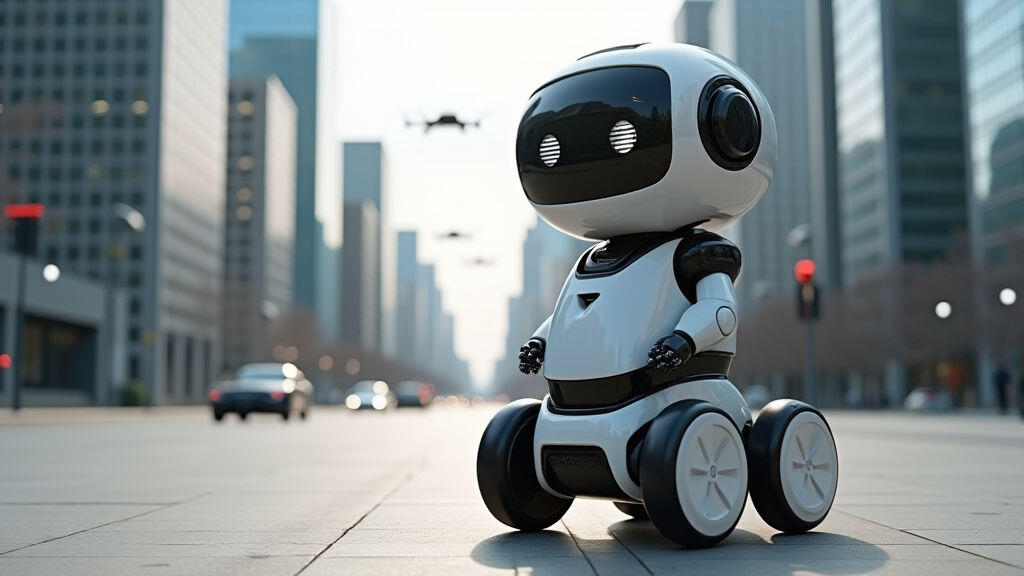

In September 2025, city governments across Europe, Asia, and North America rolled out a stunning rollout of 5G‑connected autonomous delivery robots, promising faster, greener, and more efficient last‑mile shipping. Within hours of the announcement, tweets, news outlets, and industry forums abuzz with speculations on this technology’s potential to reshape urban logistics. At the heart of these tiny robots—and the larger delivery vans that will soon glide across rooftops—lie a surprisingly humble yet indispensable component: the gear motor, also known as a reducer motor. This article explores how the surge in autonomous delivery technology is driving demand for high‑performance gear motors, what to expect from future innovations, and why this partnership could become a linchpin in a cleaner, smarter world.

Yesterday’s press releases from Amazon, DHL, and a coalition of European municipalities revealed a fleet of aerial and ground robots that will use a synchronized 5G network to navigate through streets, alleys, and even delivery drones that hover above rooftops. The main selling point? Eliminating delivery trucks on busy streets, cutting carbon footprints by up to 70%, and offering instant delivery windows that rival next‑day shipping.

While the software and AI decision‑making often fuel headlines, it’s the mechanical backbone of these robots that will determine if they can keep pace with human expectations. This is where gear motors step in.

A gear motor is a compact unit that combines a DC motor and a gearing mechanism into one assembly. It steps down the high‑speed rotation of the motor to a more manageable, high‑torque output—exactly what a robot needs to climb stairs, lift payloads, or effortlessly maneuver through congested cityscapes.

What makes gear motors especially attractive for emerging autonomous delivery systems is their:

Because autonomous robots have to end up on uneven ground—pavements, sidewalks, even grass patches—gear motors are also often paired with shock‑absorbing mounts that keep the system stable and minimize wear on the vehicle’s structural frame.

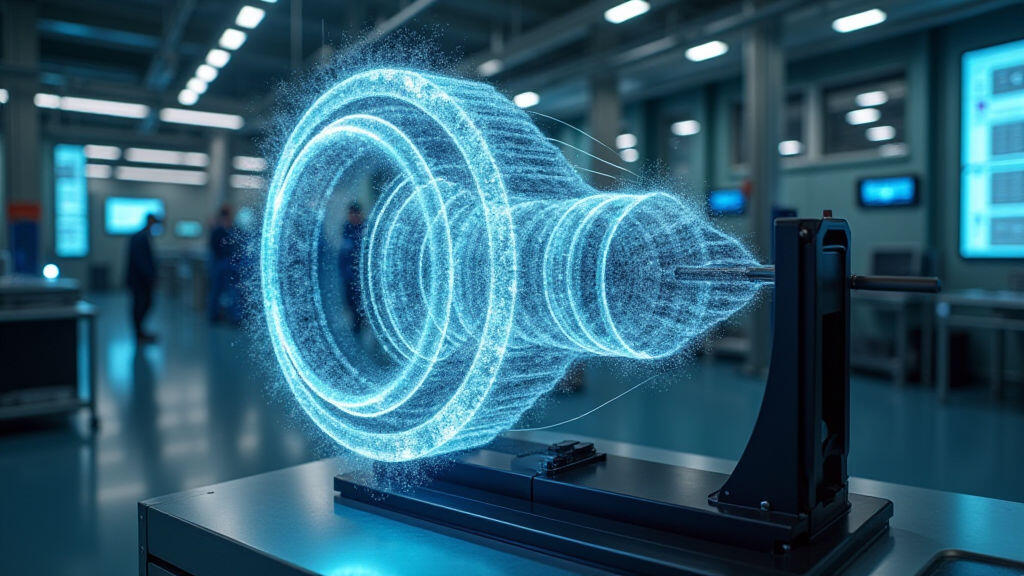

With 5G, robots gather telemetry data from their gear motors in real time. High‑frequency data streams allow the control software to detect subtle changes in torque output, anticipate bearing wear, and preemptively re‑route routes to avoid heavy traffic or shallow potholes. Consequently, manufacturers need gear motors capable of delivering accurate, repeatable torque under fluctuating load conditions—exactly what the newest high‑precision, low‑loss gear motors fulfill.

Autonomous delivery robots rely heavily on lithium‑ion packs, meaning that any inefficiency in the drivetrain quickly drains savings in range. Gear motors with lower internal friction translate to less heat generation and longer battery life. Emerging manufacturing methods, such as additive‑manufactured precision gears with minimized backlash, are drastically cutting the losses that were once a major bottleneck for robotic mobility.

The United Nations’ Sustainable Development Goals, combined with tightened European emissions directives, push for mechanically efficient systems. Gear motors that incorporate self‑diagnostics and fail‑safe torque levels are being certified in new safety standards—making them not just an option but a necessity for compliant autonomous platforms.

Recent market reports indicate that the global gear motor revenue is projected to acquire a 12% CAGR over the next five years, a sharp uptick tied to the autonomous delivery boom. Stocks of key gear motor suppliers, such as KUKA, Bosch, and a range of Chinese OEMs, have already recorded doubles in quarterly sales. This newfound prosperity highlights both the supply chain's pivot and the technology’s seeding in everyday life.

One can already anticipate that mass production lines will focus on modular gear motors that can be tailored per delivery model—small, lightweight units for sidewalk bots and heavy, high‑torque motors for over‑head delivery drones. Customizable mounting solutions and firmware‑upload capabilities will further empower operators to adapt to evolving city infrastructures.

The next generation of gear motors will likely integrate:

Combined, these advancements create a resilient feedback loop: smarter motors mean more reliable robots; reliable robots accelerate the adoption of autonomous delivery; adoption drives more refined gear motor designs. The entire ecosystem points toward reduced carbon emissions, decreased traffic congestion, and a more sustainable marine supply chain.

The recent surge of autonomous delivery robots is not merely a software marvel; it’s an integrated mechanical odyssey powered by the gear motor. As these systems scale, the demand for reliable, efficient, and small form‑factor gear motors will rise accordingly. In a world where every delivered parcel counts toward environmental goals and city livability, the humble gear motor positions itself as an unsung hero—propelling humanity toward a cleaner, smarter, and more connected future.

Leave A Reply

Your email address will not be published. Required fiels are marked